Contact Us

-

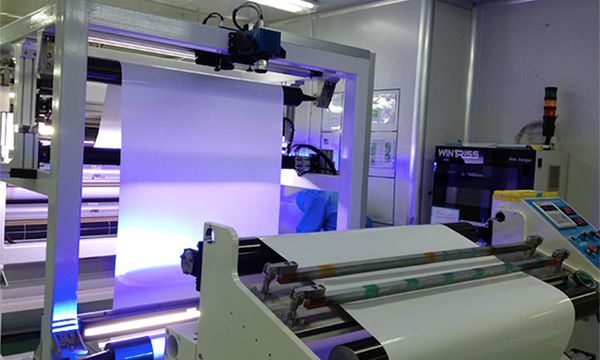

- Lithium BatteryWintriss surface inspection system can implement online detection of defects on the surface of battery separator films, battery electrodes and aluminum laminated films through the principle of machine vision inspection, while providing exact product quality information.View More

-

- Nonwoven FabricWintriss online surface inspection system comprises of smart line scan camera with high-speed processing unit and advanced lighting technology to quickly and precisely detect all defects on product surfaces.View More

-

- Solar EnergyWintriss online surface inspection system is coupled with smart line scan camera and advanced lighting technology to accomplish quick and precise detection of defects.View More

Wintriss was founded in 1989 and currently has offices located across the world. We are a leading company that designs and manufactures optical surface inspection systems, and provides surface defect detection solutions to a multitude of industries. Based on the principle of machine vision technology, we have developed smart inspection cameras which are embedded with image processing intelligence, delivering fast processing speed and high resolution. Motivated by our customers' inspection needs and quality control requirements, we strive for developing and producing automated optical inspection systems that fit a variety of markets.

Surface Inspection System

-

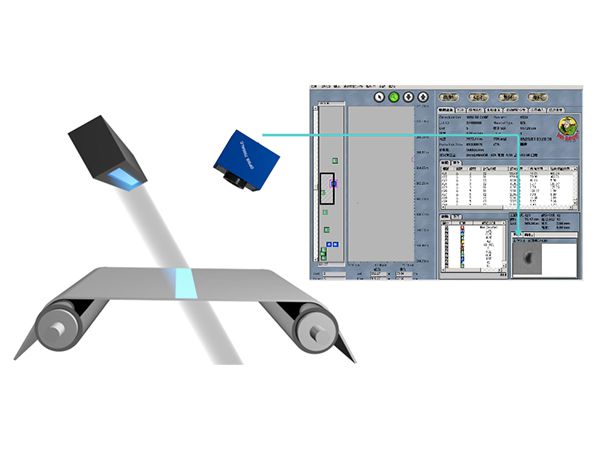

- Smart Line Scan CameraThe OPSIS 8000 smart line scan camera is a surface inspection cameras capable of capturing high-resolution images of continuous running webs.

-

- Inspection LightingIt adopts ultra-bright and long lifespan LED and Bi-Level lighting technology to restore the most realistic look of the extremely small defects on inspected webs.

-

- Detection SoftwareA powerful classification engine quickly and accurately sorts the defects into user-defined categories to aid in production quality control.