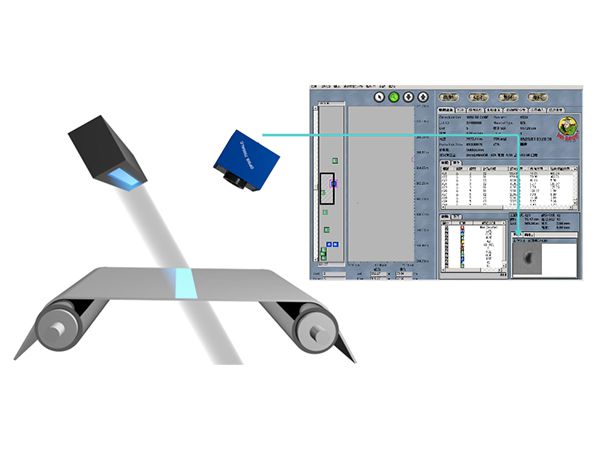

Wintriss online surface inspection system comprises of smart line scan camera with high-speed processing unit and advanced lighting technology to quickly and precisely detect all defects on product surfaces. The inspection system's modular architecture makes it configurable and flexible to accommodate the material width, production speed, and defect size of the products being inspected.

In the nonwoven industry, Wintriss surface inspection system can provide a turnkey solution for nonwoven inspection applications. By connecting with rewinder control system, the inspection system can enable the rewinder to stop automatically at the location of the detected defects, so that operator can timely remove the defective products.

Spunlace nonwoven, thermal bonded nonwoven, needle punched nonwoven, composite nonwoven, laminated nonwoven, meltblown nonwoven, spunbond nonwoven, air laid nonwoven, fiberglass cloth

Black spots, fiber agglomerates, holes, oil stains, contaminants, hair, clumps, etc.

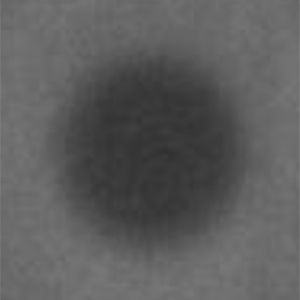

Black spot

Black spot Black spot

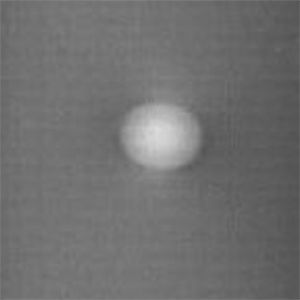

Black spot White spot

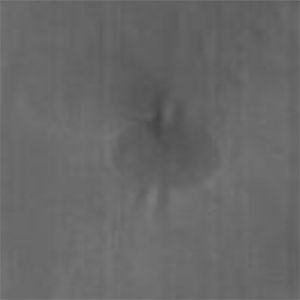

White spot Oil stain

Oil stain