Wintriss surface inspection system can detect all defects that need to be avoided by paper manufacturers, evaluate the defection position, size and grade, and perform precise defect classification based on defect size, shape and gray scale. It provides paper manufacturers with efficient solution for ensuring high quality of paper products.

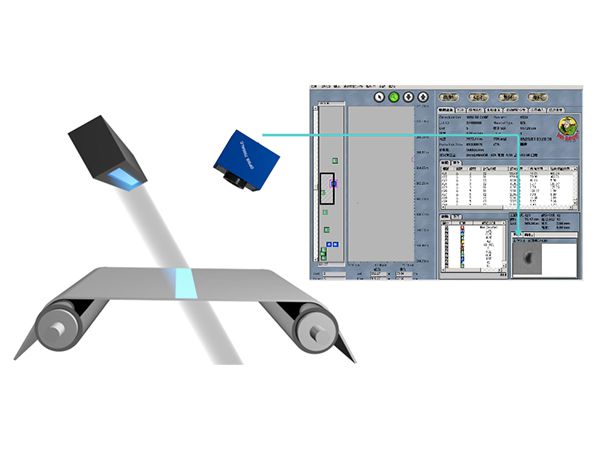

Our defect detection system adopts an OPSIS 8000 smart sensor with a built-in FPGA processing unit to detect all defects on paper surfaces quickly, precisely and consistently.

Paper Types

Commercial printing paper, converting paper, coated paper, office paper, specialty paper, etc.

Defects

Pinholes, bugs, black spots, bright spots, scratches, strips, missing coatings, creases, rough edges, folding lines, etc.

Black spot

Black spot Scratch

Scratch Crease

Crease Folding line

Folding line

Wintriss was founded in 1989 and currently has offices located across the world. We are a leading company that designs and manufactures optical surface inspection systems, and provides surface defect detection solutions to a multitude of industries. Based on the principle of machine vision technology, we have developed smart inspection cameras which are embedded with image processing intelligence, delivering fast processing speed and high resolution. Motivated by our customers' inspection needs and quality control requirements, we strive for developing and producing automated optical inspection systems that fit a variety of markets.