-

- Smart Line Scan CameraThe OPSIS 8000 smart line scan camera is a surface inspection cameras capable of capturing high-resolution images of continuous running webs.

-

- Inspection LightingIt adopts ultra-bright and long lifespan LED and Bi-Level lighting technology to restore the most realistic look of the extremely small defects on inspected webs.

-

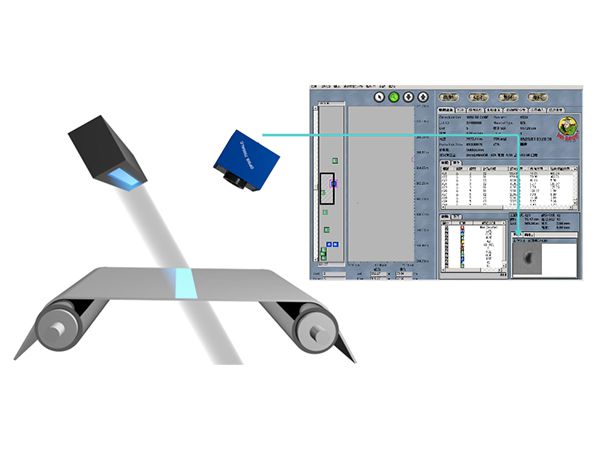

- Detection Software

A powerful classification engine quickly and accurately sorts the defects into user-defined categories to aid in production quality control.

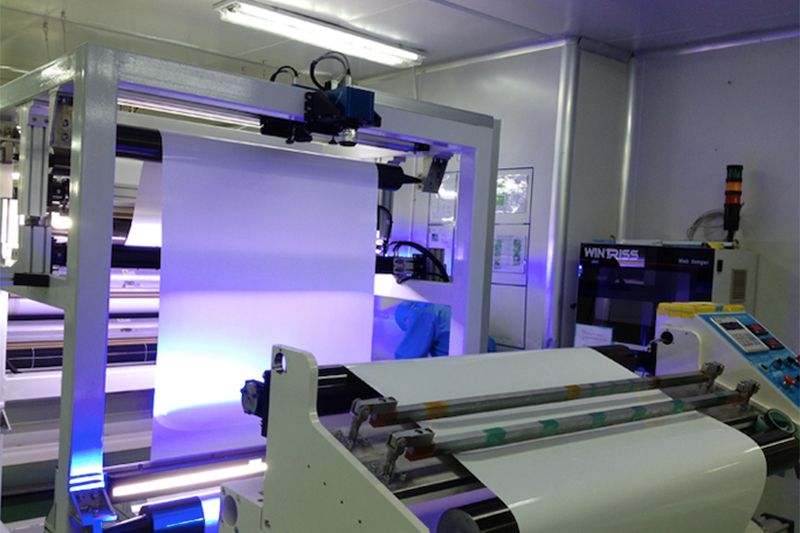

Web Ranger surface inspection system integrates smart line scan camera, patented light source and detection software to conduct online or offline inspection of moving objects in continuous webs or sheets, providing an efficient way to detect defects on product surface and provide exact product quality information. The modular design of the inspection system enables it to be configurable and flexible to adapt to the material width, production speed and defect size of products being inspected.

Web Ranger surface inspection system features an OPSIS 8000 smart sensor with a built-in FPGA processing unit to detect defects on product surfaces quickly, precisely and consistently. This defect detection system can be offered with independent cooling system to ensure that the smart sensor runs stably even in harsh working conditions.

The stable VxWorks operating system inside the smart line scan camera is adopted for its high reliability and outstanding real-time behavior, making the system suitable for communication, military, aerospace, and other industries that require cutting-edge technology, high accuracy and timeliness of data provided.

The advanced intelligent defect classification engine can precisely identify defect types based on defect images, assisting manufacturers in enhancing quality management and further improving production process. All data of defects detected by the surface inspection system will be clearly shown on the display in real time, and stored in an SQL database. The production quality report is developed based on Microsoft SQL Server, giving manufacturers a customizable way to generate different production quality reports.

- Precise defect detection: coupled with patented technology, the inspection system adopts independently developed 8K smart line scan camera with 640MHz fast processing speed and high resolution to guarantee the realistic defect image which is proportional to the defect physical size and shape without deformation.

- Bi-Level lighting technology: it provides high-clarity 3D images of defects, by which user can accurately identify the defect types and the cause of defect formation.

- Ultra-bright patented LED light source: advanced LEDs are used to deliver high brightness while ensuring good luminous efficiency and excellent heat dissipation, the service life of these LED light source exceeds 100,000 hours.

- Artificial intelligence algorithm-based software: it achieves deep self-learning to precisely locate and classify the defects, thus implementing the precise detection of hard-to-find defects that are often missed by manual inspection.