Wintriss surface inspection system is an efficient defect detection solution for manufacturers to improve the quality of film products. This inspection system allows user to select the specific defects, and evaluates the defection position, size and grade, as well as performs precise defect classification based on defect size, shape and gray scale.

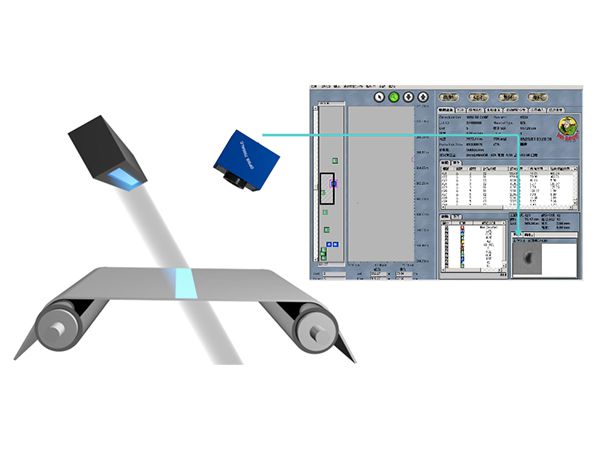

Integrated with high resolution smart line scan camera and coupled with long lifespan LED light source, the surface inspection system is based on the machine vision inspection concept to conduct online surface defect detection of various films and provide exact quality information. The modular design of the inspection system can be flexibly configured according to the material width, production speed and defect parameters of the film product.

- Packaging films / specialty films:

BOPP, BOPET, BOPA, CPP, PVC, CPE, blown film, cast film, PI, PVB, APET, ABS, PC/PMMA, hygienic film, aluminized film, semi-cured film, etc. - Optical films:

optical grade BOPET, polarizer film, prism film, TAC, OPF, window film, dry film, PVA, 3D film, light guide plate, optical protective film, BEF, diffusion film, anti-reflective film, anti-glare film, LCP film, CPI film, etc.

Bright spots, dark spots, scratches, micro scratches, gels, bumps, streaks, voids, stains, pinholes, crease, folds, foreign contaminants, etc.

Dark spot

Dark spot Scratches

Scratches Bright spot

Bright spot