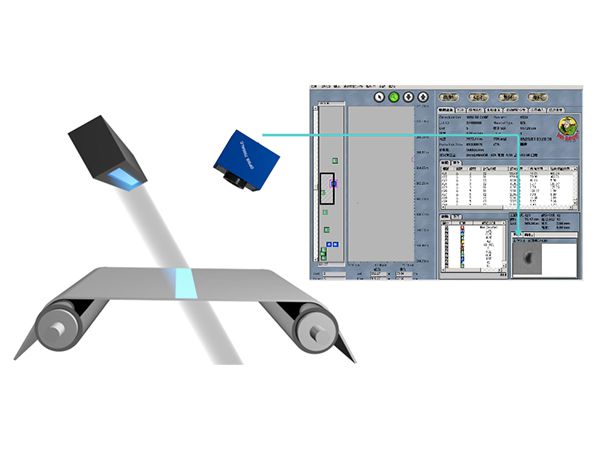

Wintriss online surface inspection system is coupled with smart line scan camera and linear light source to accomplish quick and precise detection of defects. It adopts artificial intelligence algorithm-based software to achieve deep self-learning to perform precise defect detection and classification, allowing it to detect hard-to-find defects that manual inspection often misses.

VxWorks operating system is adopted for its high reliability and outstanding real-time behavior, making Wintriss surface inspection system suitable for communication, military, aerospace, and other industries that require high accuracy and timeliness of data provided.

Fiberglass cloth, impregnated fiberglass cloth, copper foil, polyimide film (PI), flexible copper clad laminate (FCCL), and CCL copper base substrate

- Fiberglass cloth:

fiber protrusion, crazing, measling, black spots, water marks, pimples, pits, pinholes, crease, rough edges, etc. - Impregnated fiberglass cloth:

black spots, bugs, fish eyes, pin holes, etc. - Copper foil:

oxidation spots, bumps, black spots, bugs, stains, water marks, pinholes, creases, fold lines, etc. - Polyimide film (PI):

air bubbles, contaminants, black spots, bugs, bumps, white spots, scratches, oxidation spots, etc. - Flexible copper clad laminate (FCCL):

air bubbles, contaminants, black spots, bugs, bumps, white spots, scratches, oxidation spots, gauge bands, etc. - CCL copper base substrate:

oxidation spots, bumps, black spots, bugs, contaminants, bugs, pinholes, scratches, fibers, etc.

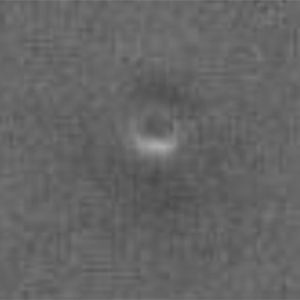

Bump

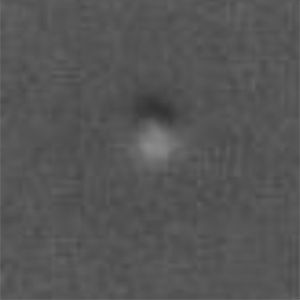

Bump Bump

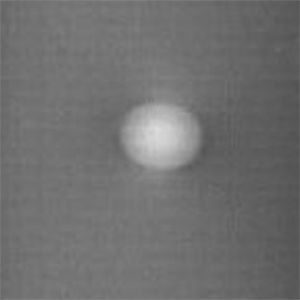

Bump White spot

White spot Oil stain

Oil stain