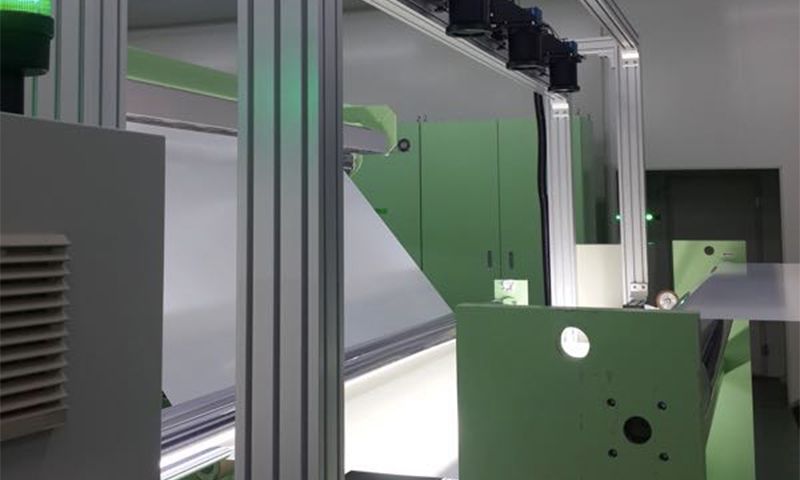

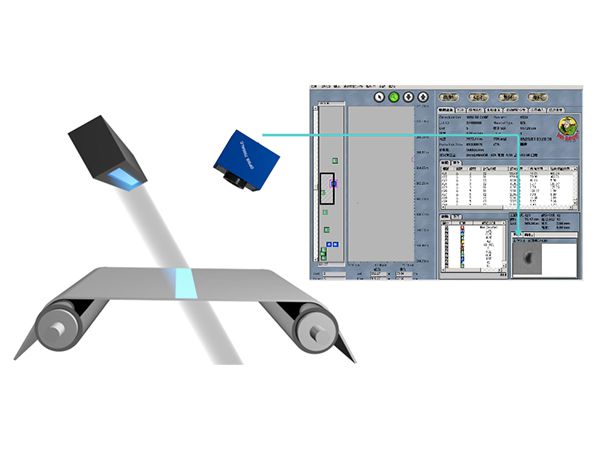

Wintriss surface inspection system can implement online detection of defects on the surface of battery separator films, battery electrodes and aluminum laminated films through the principle of machine vision inspection, while providing exact product quality information. The artificial intelligence-based defect detection system adopts deep self-learning algorithms to locate the defect, therefore achieving defect detection and classification.

In response to the rigid requirements of power battery inspection regarding aspects of accuracy and consistency, the surface inspection system is configured with smart line scan camera and vision software to precisely detect various surface defects during the battery production process and provide high clarity of images. It is ideal for battery manufacturers to improve production efficiency while guaranteeing the quality of products.

- Battery separator film defect detection:

holes, oil spots, tears, delamination, bright spots, dark lines, white spots, scratches, voids, gels, roll impression, oil stains, water stains, contaminants, streaks, etc. - Battery electrode defect detection:

scratches, missing coatings, contaminants, foreign particles, wrinkles, defective edges, dark spots, cracks, misplacements, color difference, metal residues, dents, bumps, fold lines, etc. - Battery aluminum laminated film defect detection:

bumps, dents, contaminants, stains, voids, gels, unevenness, air bubbles, wrinkles, scratches, fish scales, rust residuals, dark spots, fish eyes, pinholes, foreign particles, etc.

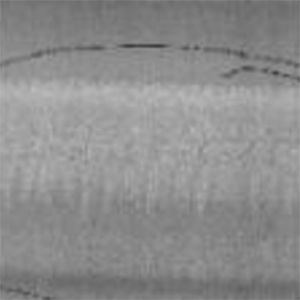

Streak

Streak White spot

White spot Oil stain

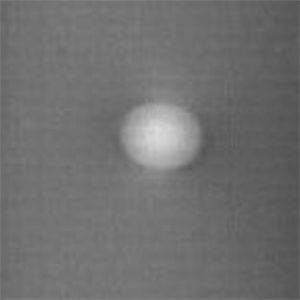

Oil stain Pinhole

Pinhole