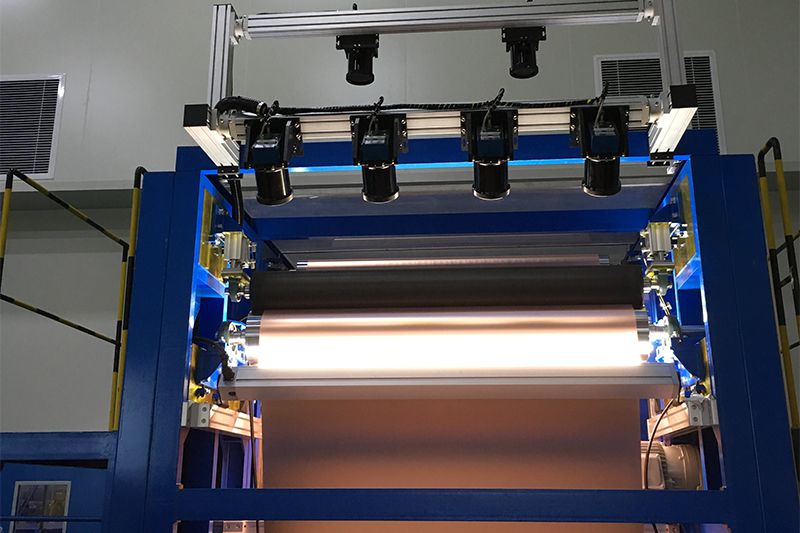

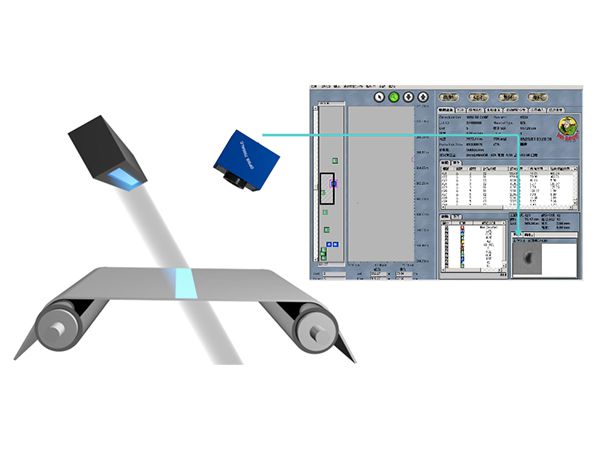

Wintriss online surface inspection system is capable of real-time monitoring and inspection of production quality, ensuring that the defects of products can be detected in a timely manner. It provides an effective way for surface inspection of sheet metals throughout the entire production process, thus ensuring the high quality of final products.

Our surface inspection system is configured with a standard intelligent defect classification engine that can precisely identify defect types according to the defect images, helping metalworking manufacturers enhance their quality management and improve their production process.

Aluminum, aluminum alloy foil, copper, stainless steel, zinc/tin/nickel/chrome plated sheet metal, coated foil, etc.

Pinholes, wrinkles, oil stains, bumps, corrosion spots, scratches, folding lines, black spots, burrs, bugs, roll marks, etc.

Folding line

Folding line Wrinkle

Wrinkle Black spot

Black spot Black spot

Black spot